Laser Safety Program

Background

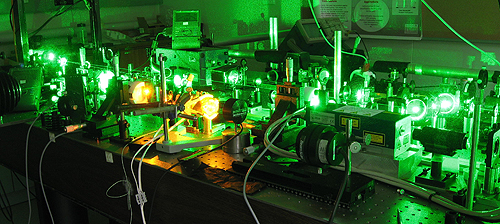

Lasers and laser systems are regulated by the Texas Department of State Health Services – Bureau of Radiation Control. To comply with this code, The University of Texas Rio Grande Valley (UTRGV) has established a Laser Safety Program administered by the Department of Environmental Health, Safety and Risk Management (EHSRM).

The Laser Safety Program's mission is to assist in maintaining safe and healthy settings for research and clinical activities and oversee the use of lasers in the UTRGV environment. The program fulfills this mission by providing consulting services to the laser users, performing routine laboratory inspections, providing personnel, area and environmental monitoring, and responding to emergency situations. Please feel free to contact us if we may be of assistance or if you have any safety concerns.

Applicable Regulations

TAC 25 Teas Administrative Code

This program is established to meet the requirements of 25 Texas Administrative Code 289.301 entitled (Registration and Radiation Safety Requirements for Lasers and Intense-Pulsed Light Devices) and 25TAC rules §289.203, §289.204, §289.205, §289.231 prudent safety practice. If any conflict occurs between this program and the code, the latter shall prevail.

American National Standards Institute (ANSI)

The voluntary, consensus, user standard, ANSI Z136.1 – American National Standard for Safe Use of Lasers, is also incorporated by reference into the state of Texas regulation 25TAC289.301 and is used extensively by EHS for hazard analysis and determination of applicable control measures. ANSI Z136 is recognized by OSHA (Occupational Safety and Health Administration). State and local government workers are not covered by federal OSHA in Texas but many of the state’s regulations and policies emulate OSHA. The secretariat and publisher for the ANSI Z136 laser safety series is the Laser Institute of America.

- ANSI Z136.1-2014, American National Standard for Safe Use of Lasers (replaces ANSI Z136.1-2007)

- ANSI Z136.2-2012, American National Standard for Safe Use of Optical Fiber Communication Systems Utilizing Laser Diode and LED Sources (replaces ANSI Z136.2-1997)

- ANSI Z136.3-2018, American National Standard for Safe Use of Lasers in Health Care (replaces ANSI Z136.3-2011)

- ANSI Z136.4-2021, American National Standard Recommended Practice for Laser Safety Measurements for Hazard Evaluation (replaces ANSI Z136.4-2010)

- ANSI Z136.5-2020, American National Standard for Safe Use of Lasers in Educational Institutions (replaces ANSI Z136.5-2009)

- ANSI Z136.6-2015, American National Standard for Safe Use of Lasers Outdoors (replaces ANSI Z136.6-2005)

- ANSI Z136.7-2020, American National Standard for Testing and Labeling of Laser Protective Equipment (replaces ANSI Z136.7-2008)

- ANSI Z136.8-2021, American National Standard for Safe Use of Lasers in Research, Development, or Testing (replaces ANSI Z136.8-2012)

- ANSI Z136.9-2013, American National Standard for Safe Use of Lasers in Manufacturing Environments (first edition)

- ANSI Z136.10 (proposed), Safe Use of Laser in Entertainment, Displays and Exhibitions (in committee)

All laser products sold in the United States must comply with The Performance Standards for Light Emitting Products (Part 1040) which includes the regulations formerly known as The Federal Laser Product Performance Standard (FLPPS) of the CDRH (21CFR1040.10 and 21CFR1040.11). A compliance guide is available for certifying laser products where this requirement is applicable.

If a laser is built in-house at the university then it does not have to be certified with the federal performance standards provided that it is

- operated only by the individuals who built it

- not mass produced

- not offered into commerce

- not relocated from its original site

Custom Built and Modified Lasers

However, EHS must still be notified to determine the appropriate hazard class, perform a risk assessment and provide review/approval prior to operation. A laser may not be modified from its original condition unless EHS has reviewed and approved the modification as the laser class and subsequent safety control measures may need to be adjusted.

Internal Registration

- Each Class 3b and Class 4 laser in the possession of the university, regardless of the actual owner of the laser, must be registered with UTRGV Department of Environmental Health, Safety and Risk Management.

- The laser class is typically determined by the laser manufacturer and can be found on a label on the laser. If the laser is missing the label or it is “homemade,” contact EHSRM to determine the classification.

- Multiple lasers may be registered to a single Permittee. However, a single laser may not be registered to multiple Permittees. If a laser is to be transferred to another UTRGV Permittee (or another institution), inform EHSRM of the change.

- Class 3b and Class 4 lasers that are an integral part of a product that is classified as a Class 1, Class 2, or Class 3a laser product do not need to be registered.

Instructions

- Complete a Laser Device Registration to the EHSRM.

- The EHSRM will then notify the Principal Investigator to determine if the necessary controls are in place in order to meet the applicable standards.

- All individuals using the laser must attend Laser Safety Training prior to the use of the laser.

- Minors are prohibited from working with Class IIIB and Class IV lasers that are unprotected.

- Contact EHSRM before sending any laser (all classes) to Surplus Property or transferring the laser to another Principal Investigator.

Standard Operating Procedures

It is strongly recommended that users prepare a written Standard Operating Procedure (SOP) for the use of the laser to ensure that all personnel are thoroughly familiar with the use of the laser. It should include, at a minimum, the following information:

- A statement that Class 3B and 4 lasers may only be operated, maintained, and serviced by authorized personnel or by the manufacturer’s representative

- Emergency call list

- Description of safety features

- Description of protective equipment laser operators must use

- Specific operating procedures, from start-up to shut-down

- Specific alignment procedures

- Safety checklist, either provided with the equipment or developed by the PI

- Emergency instructions

- Keep the SOP near the laser, readily available for use by operators and service personnel.

- Survey the workplace periodically to ensure compliance with your SOP and laser safety requirements.

Personal Protective Equipment

All users of class III and Class IV lasers are required to use the appropriate personal protective equipment. The Laser safety Officer is available to assist PIs with hazard calculations and fit for correct eyewear as required for laser use approval.

- Eyewear: Laser safety eyewear is required in the presence of class 3B and 4 lasers. The eyewear must provide sufficient protection for the user.

When selecting eyewear, consider:

- Wavelength of laser output

- Potential for multi-wavelength operation

- Optical density

- Visible light transmission

- Femto second rated, if applicable

- Peripheral vision

- Need for prescription glasses

- Degradation of absorbing media, such as photo-bleaching

- Capacity of the front surface to produce specular reflection

- Radiant exposure or irradiance and the corresponding time factors at which laser protective eyewear damage occurs, including transient bleaching

- Strength and shock-resistance of materials

- Comfort and fit

- Skin protection: Skin protection is required if personnel are likely to be chronically exposed to scattered ultraviolet light (UV), such as during excimer laser applications, or acutely exposed to levels greater that the maximum permissible exposure (MPE) limit for skin.

o Important: Laser light can be attenuated by layered clothing. However, the nylon-based material used for many lab coats has a transmission level of 20% to 40%, and is not appropriate as personal protective equipment.- Use leather gloves, aprons, and jackets for protection against UV exposure.

- Wear fire-resistant materials and UV protection for work with class 4 lasers.

Other personal protective equipment may be required when engineering controls are insufficient. This may include:

- Respirators

- Hearing protection

Training

Laser safety training is mandated for all personnel prior to working with class III and class IV lasers. Awareness training is provided for those who share a research laboratory with a Principal Investigators (PIs) conducting research with lasers. Training can be arranged by contacting the UTRGV representative.

All personnel using laser are required to have specific training in the use of the laser in accordance with written Standard Operating Procedures.

Laser Program Documents

Forms

- UTRGV – Laser Device Registration

- UTRGV – Laser Transfer Form

- UTRGV – Laser Safety Survey

- UTRGV – Non Radiation Hazard Survey