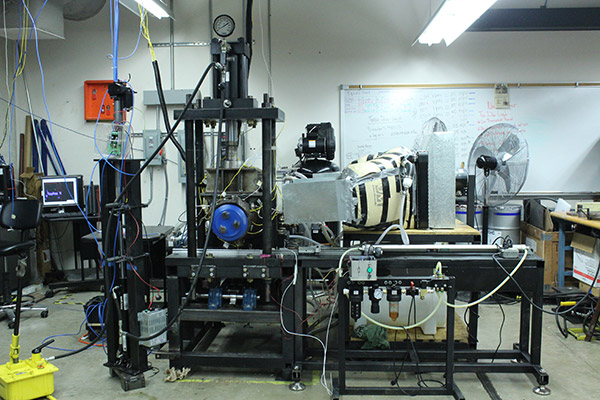

Single Bearing Tester

The Single Bearing Tester allows UTCRS researchers to analyze and characterize the thermal and dynamic performance of all railroad bearing classes used in North America and Canada. State-of-the-art bearing condition monitoring systems are employed that can detect the onset of bearing defect formation or failure. The UTCRS Single Bearing Tester is designed to provide up to 5,000 lbf of lateral load, a variable frequency (0-4 Hz) impact load, in addition to static vertical loads of up to 60,000 lbf applied to a single railroad bearing. As part of a new project funded through the 2015CY call for proposals, UTCRS researchers designed and implemented a unique system that can be used to assess the efficacy and accuracy of the current wayside thermal detector systems employed in our rail network. Since it is not feasible to have the railroad bearing pass over the infrared thermal detector at speeds of 30-35 mph in a laboratory setting, UTCRS researchers devised a fully-automated pneumatic system that allows the infrared thermal detector to sweep underneath the bearing at speeds that can range anywhere from 5 to 35 mph. The focus of this study is to quantify the accuracy and limitations of the current wayside thermal detectors, and identify ways to optimize their use in field service.