Scalable and Facile in Situ Synthesis of Nanoparticles Resulting in Decorated Multifunctional Fibers

Scalable and Facile in Situ Synthesis of Nanoparticles Resulting in Decorated Multifunctional Fibers

Description

The present technology is a method for facile, scalable synthesis of nanocrystalline structure materials in situ. Nanofibers are produced with a heterogeneous surface on which the decorating surface structures are produced simultaneous with the nanofiber formation.

Problem

Current methods for decorating fibers use electrochemical deposition, ultraviolet irradiation, immersion-photoreduction, and chemical reduction, which are expensive and time consuming.

Solution

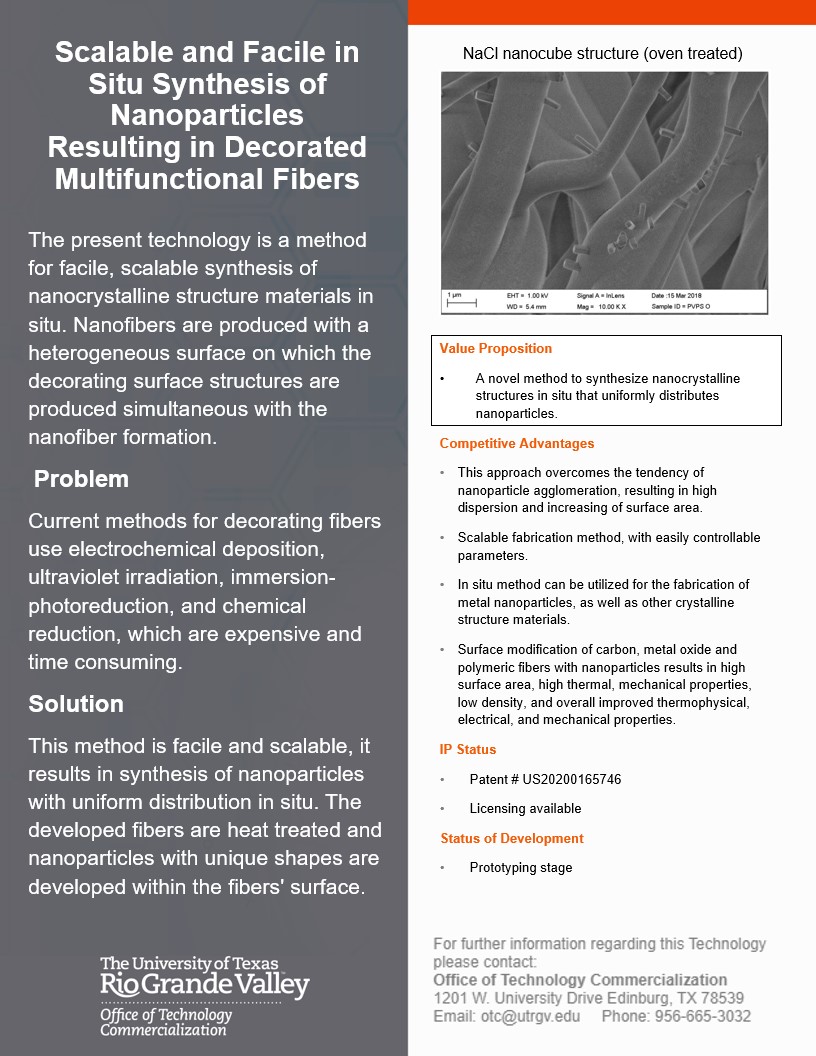

This method is facile and scalable, it results in synthesis of nanoparticles with uniform distribution in situ. The developed fibers are heat treated and nanoparticles with unique shapes are developed within the fibers' surface.

Value Proposition

A novel method to synthesize nanocrystalline structures in situ that uniformly distributes nanoparticles.

Competitive Advantages

- This approach overcomes the tendency of nanoparticle agglomeration, resulting in high dispersion and increasing of surface area.

- Scalable fabrication method, with easily controllable parameters.

- In situ method can be utilized for the fabrication of metal nanoparticles, as well as other crystalline structure materials.

- Surface modification of carbon, metal oxide and polymeric fibers with nanoparticles results in high surface area, high thermal, mechanical properties, low density, and overall improved thermophysical, electrical, and mechanical properties.

Status of Development

Prototyping stage

IP Status

- Patent #US20200165746

- Licensing available