Method and Use of Ceramic/Carbon Composite Nanofibers as Anode Materials for Lithium-ion and Sodium-ion Batteries

Method and Use of Ceramic/Carbon Composite Nanofibers as Anode Materials for Lithium-ion and Sodium-ion Batteries

Description

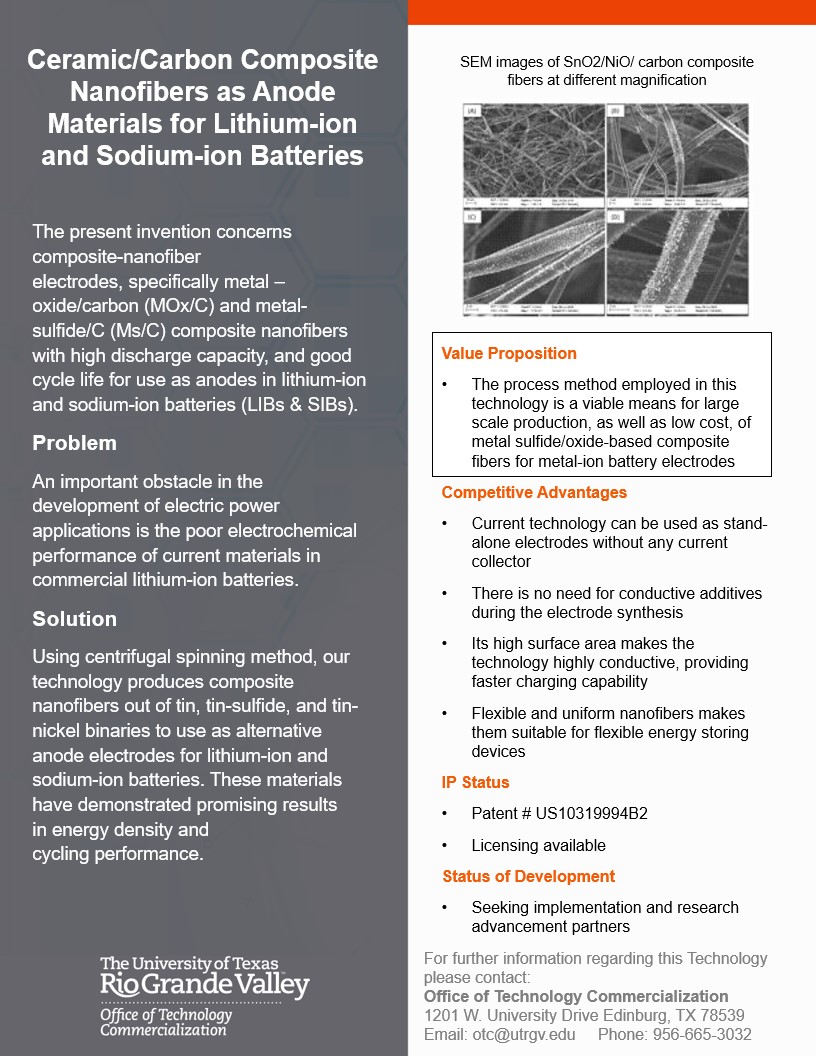

The present invention concerns composite-nanofiber electrodes, specifically metal –oxide/carbon (MOx/C) and metal-sulfide/C (Ms/C) composite nanofibers with high discharge capacity, and good cycle life for use as anodes in lithium-ion and sodium-ion batteries (LIBs & SIBs).

Problem

An important obstacle in the development of electric power applications is the poor electrochemical performance of current materials in commercial lithium-ion batteries.

Solution

Using centrifugal spinning method, our technology produces composite nanofibers out of tin, tin-sulfide, and tin-nickel binaries to use as alternative anode electrodes for lithium-ion and sodium-ion batteries. These materials have demonstrated promising results in energy density and cycling performance.

Value Proposition

The process method employed in this technology is a viable means for large scale production, as well as low cost, of metal sulfide/oxide-based composite fibers for metal-ion battery electrodes.

Competitive Advantages

- Current technology can be used as stand-alone electrodes without any current collector

- There is no need for conductive additives during the electrode synthesis

- Its high surface area makes the technology highly conductive, providing faster charging capability

- Flexible and uniform nanofibers makes them suitable for flexible energy storing devices

Status of Development

Seeking implementation and research advancement partners

IP Status

- Patent #US10319994B2

- Licensing available