A Process Model for Selective Laser Alloying

A Process Model for Selective Laser Alloying

Description

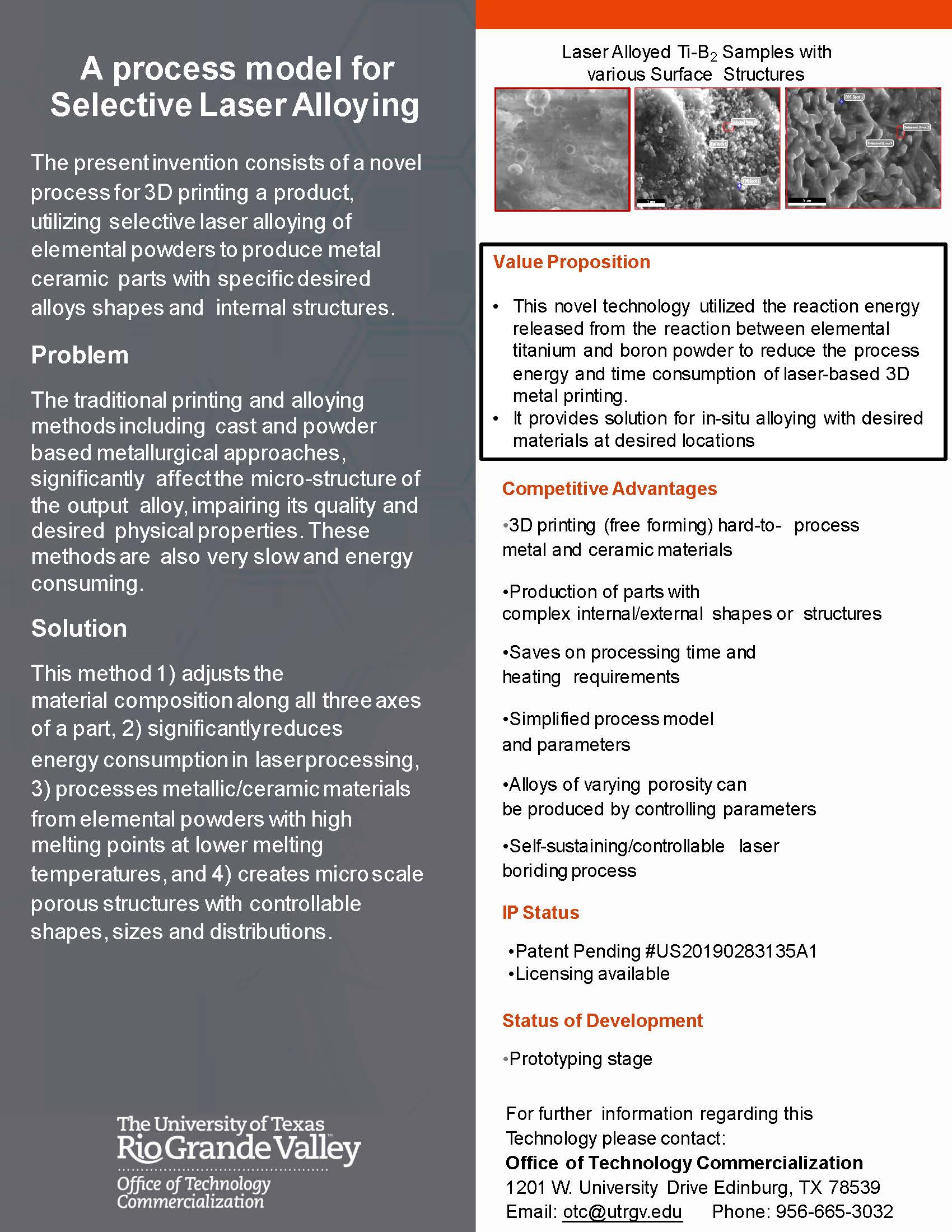

The present invention consists of a novel process for 3D printing a product, utilizing selective laser alloying of elemental powders to produce metal ceramic parts with specific desired alloys shapes and internal structures.

Problem

The traditional printing and alloying methods including cast and powder based metallurgical approaches, significantly affect the micro-structure of the output alloy, impairing its quality and desired physical properties. These methods are also very slow and energy consuming.

Solution

- Adjusts the material composition along all three axes of a part

- Significantly reduces energy consumption in laser processing

- Processes metallic/ceramic materials from elemental powders with high melting points at lower melting temperatures

- Creates microscale porous structures with controllable shapes, sizes and distributions

Value Proposition

- This novel technology utilized the reaction energy released from the reaction between elemental titanium and boron powder to reduce the process energy and time consumption of laser-based 3D metal printing.

- It provides solution for in-situ alloying with desired materials at desired location.

Competitive Advantages

- 3D printing (free forming) hard-to-process metal and ceramic materials

- Production of parts with complex internal/external shapes or structures

- Saves on processing time and heating requirements

- Simplified process model and parameters

- Alloys of varying porosity can be produced by controlling parameters

- Self-sustaining/controllable laser boriding process

Status of Development

Prototyping stage

IP Status

- Patent Pending #US20190283135A1

- Licensing available