Wireless Sensors in Injection Molds

Wireless Sensors in Injection Molds

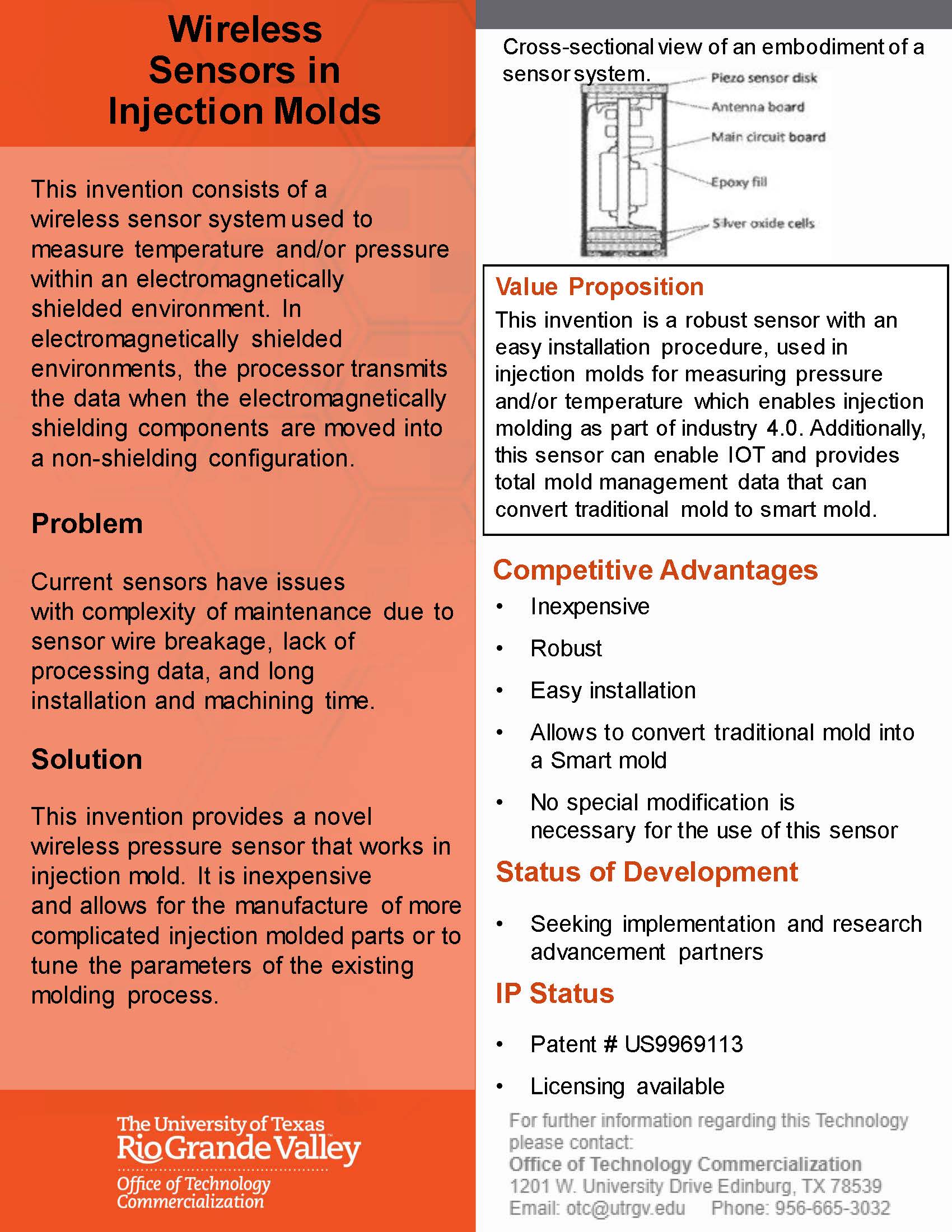

Description

This invention consists of a wireless sensor system used to measure temperature and/or pressure within an electromagnetically shielded environment. In electromagnetically shielded environments, the processor transmits the data when the electromagnetically shielding components are moved into a non-shielding configuration.

Problem

Current sensors have issues with complexity of maintenance due to sensor wire breakage, lack of processing data, and long installation and machining time.

Solution

This invention provides a novel wireless pressure sensor that works in injection mold. It is inexpensive and allows for the manufacture of more complicated injection molded parts or to tune the parameters of the existing molding process.

Value Proposition

- Inexpensive

- Robust

- Easy installation

- Allows to convert traditional mold into a Smart mold

- No special modification is necessary for the use of this sensor

Competitive Advantages

- 3D printing (free forming) hard-to-process metal and ceramic materials

- Production of parts with complex internal/external shapes or structures

- Saves on processing time and heating requirements

- Simplified process model and parameters

- Alloys of varying porosity can be produced by controlling parameters

- Self-sustaining/controllable laser boriding process

Status of Development

Seeking implementation and research advancement partnersIP Status

- Patent #US9969113

- Licensing available