Facile Method to Produce Carbon Fibers Through Acid Vapors

Facile Method to Produce Carbon Fibers Through Acid Vapors

Description

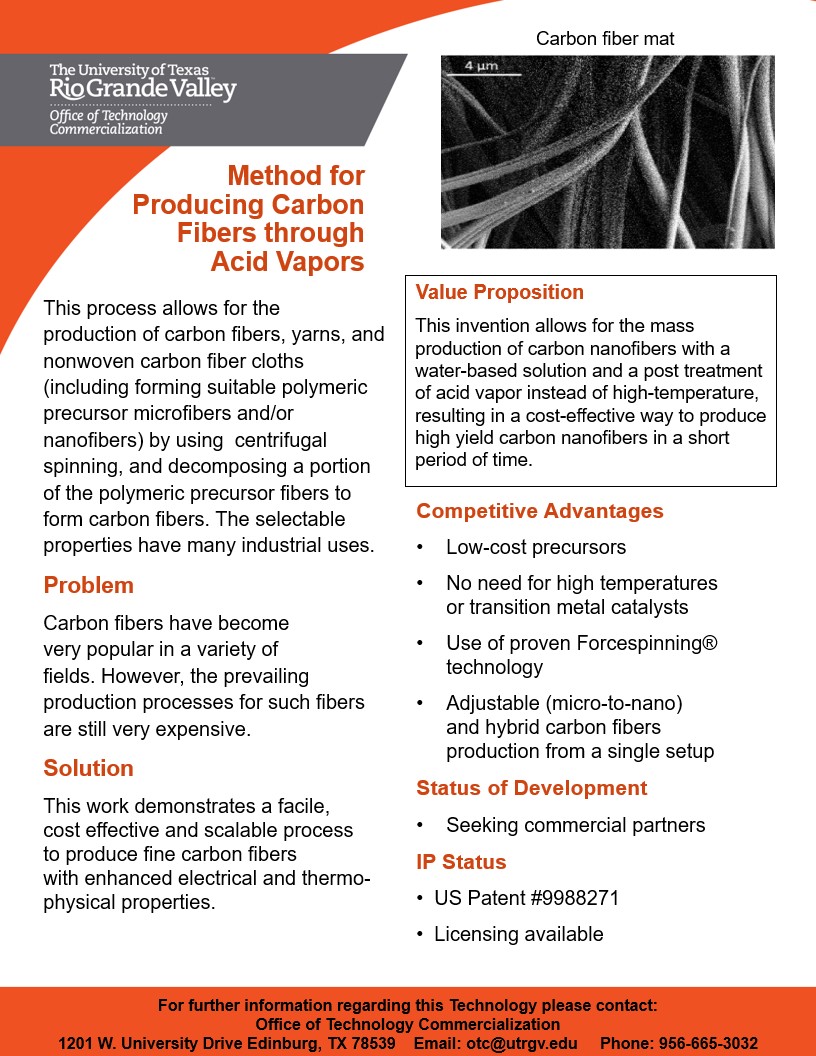

This process allows for the production of carbon fibers, yarns, and nonwoven carbon fiber cloths (including forming suitable polymeric precursor microfibers and/or nanofibers) by using centrifugal spinning and decomposing a portion of the polymeric precursor fibers to form carbon fibers. The selectable properties have many industrial uses.

Problem

Carbon fibers have become very popular in a variety of fields, however, the prevailing production processes for such fibers are still very expensive.

Solution

This work demonstrates a facile, cost effective and scalable process to produce fine carbon fibers with enhanced electrical and thermo-physical properties.

Value Proposition

This invention allows for the mass production of carbon nanofibers with a water-based solution and a post treatment of acid vapor instead of high-temperature, resulting in a cost-effective way to produce high yield carbon nanofibers in a short period of time.

Competitive Advantages

- Low-cost precursors

- No need for high temperatures or transition metal catalysts

- Use of proven Forcespinning® technology

- Adjustable (micro-to-nano) and hybrid carbon fibers production from a single setup

Status of Development

Seeking commercial partners

IP Status

- US Patent #9988271

- Licensing available