Materials Science and Materials Physics

In situ Resource Utilization (ISRU) of Lunar Regolith

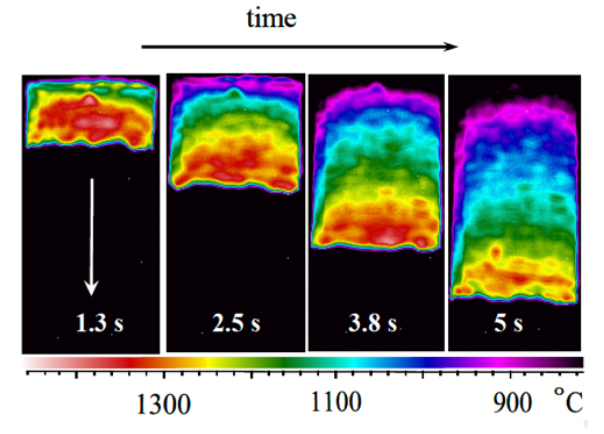

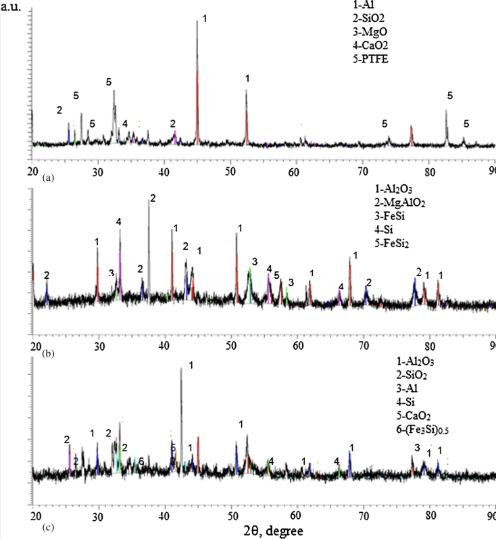

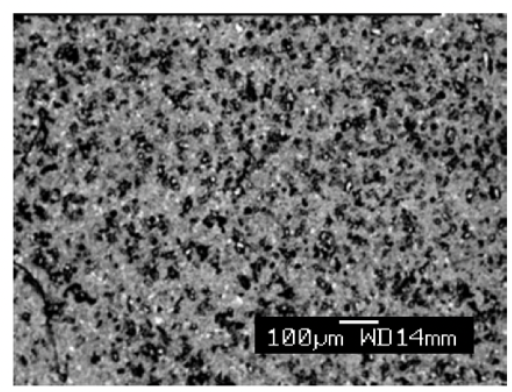

Our research on consolidating lunar regolith simulant through combustion synthesis focuses on using an innovative technique to process and stabilize regolith material. By applying combustion synthesis, we can potentially create solidified structures from lunar soil simulant that are durable enough for construction on the Moon. This approach could advance sustainable lunar exploration by supporting infrastructure needs such as habitats and landing pads, minimizing reliance on materials transported from Earth. Our group demonstrated a novel approach to consolidating lunar regolith using highly exothermic reactions as well as thermite reactions of lunar regolith simulant with aluminum or magnesium, resulting in the production of consolidated ceramic materials for potential construction applications on the Moon.

Research on lunar regolith consolidation is critical for ensuring the success of sustained lunar exploration. The ISRU approach could revolutionize space exploration by creating a “living off the land” paradigm, allowing future explorers to utilize resources on-site rather than depending solely on supplies from Earth. By addressing the challenges of utilizing local resources effectively, researchers can help lay the groundwork for permanent lunar settlements and support broader exploration goals, including potential missions to Moon, Mars and beyond.

Figure: (left) - IR thermal images obtained during the combustion synthesis of lunar regolith simulant (JSC-1); (center) - X-ray powder diffraction analysis of (a) initial mixture; (b) the reaction product at the combustion front (quenched conical sample); (c) sintered product; (right) - Scanning electron micrograph of JSC-1 composite.

Carbon‑based Nanocomposite Yarns

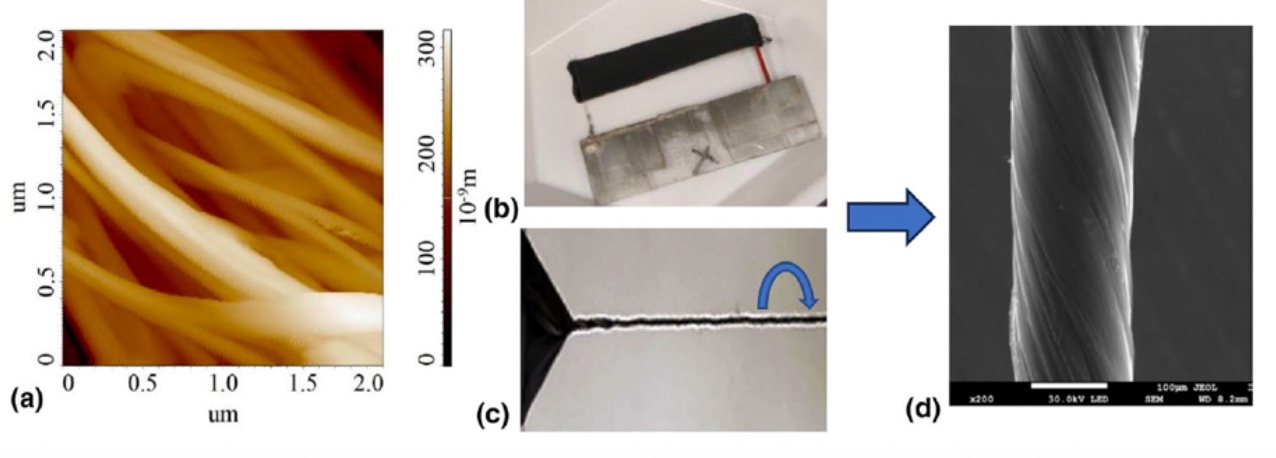

Research on carbon-based nanocomposite yarns involves the integration of energetic systems with carbon nanotubes (CNTs) or graphene to enhance energy release, electrical conductivity, and mechanical strength, enabling multifunctional materials for advanced sensing, actuation, and energy conversion applications. Recently, carbon-based twisted laminar yarns were fabricated by the homogeneous incorporation of titanium and graphene nanoparticles into carbon multi-wall carbon nanotube (MWNT) sheets. The titanium and graphene reacted to form titanium carbide (TiC) within the MWNT host matrix when ignited by heating. The reaction between titanium and graphene within the MWNT results in the generation of 50 J/g of released heat. This indicates a roughly 28% increase in heat discharge compared to the exothermic reaction when only pure titanium and graphene are involved. The produced yarns have a Young’s modulus of 1.9 GPa, indicating ~ 200% enhancement compared to the 0. 63 GPa observed for the pristine yarn.

Figure: (a) AFM image of a MWNT sheet. (b) MWNT sheets coated with a Ti/GRN mixture. (c) A Ti/GRN-MWNT sheet being twisted 10 times into a laminar composite yarn, (d) Scanning electron microscope (SEM) image of a Ti/GRN-MWNT yarn.

Development of Janus-like Particles of Magnetoelectric Materials

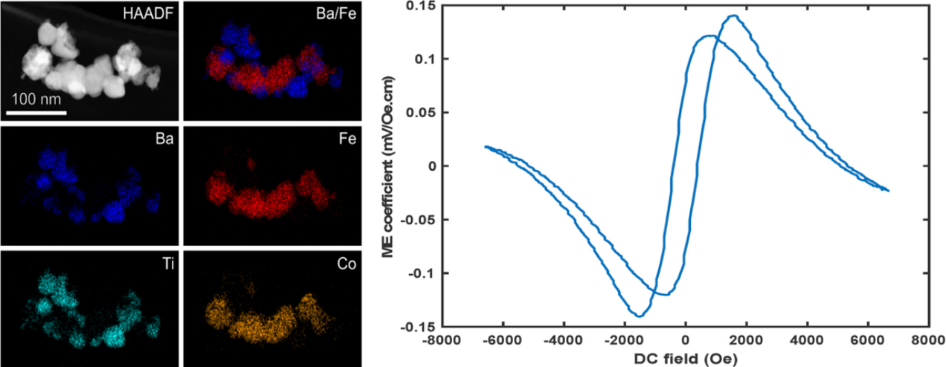

Using carbon combustion synthesis of oxides, our team achieved rapid and energy-efficient production of a multiferroic cobalt ferrite–barium titanate composite with a Janus-like particle matrix structure.The exothermic oxidation of carbon nanoparticles with an average size of 5 nm and a specific surface area of 110 m 2 /g generates a self-propagating thermal wave with peak temperature of up to 1000 ◦ C. The thermal front rapidly propagates through the mixture of solid reactants (magnetic- CoFe 2 O 4 and ferroelectric-BaTiO 3 ) and results in localized hot-spot sintering of magneto-electric phases to form a nanocomposite structure. Carbon is not incorporated in the product and is emitted as a gaseous CO 2 . Existence of discrete CoFe 2 O 4 and BaTiO 3 phases in the composites nanostructures was confirmed using X-ray powder diffraction along with SEM and TEM analysis. We estimated the activation energy for the combustion synthesis of Janus-like particles to be 112 ± 3.3 kJ/mol, indicating that the barium titanate and cobalt ferrite presence decrease the activation energy barrier of carbon oxidation and facilitate the ignition process of the combustion synthesis. We observe that the as-synthesized samples show magnetoelectric coupling on multiferroic cobalt ferrite–barium titanate ceramic composites.

Figure: (left) – HAADF-STEM image and complementary STEM-EDX elemental maps of a BaTiO₃/CoFe₂O₄ agglomerate. A Ba/Fe overlaid STEM-EDX elemental map is also shown. (3-pixel Gaussian blur was applied to the STEM-EDX maps to aid visualization); (right) – Magnetoelectric coefficient of BaTiO₃/CoFe₂O₄ as a function of external DC magnetic field.

Metastable Intermolecular Composites and Nanoenergetic Materials

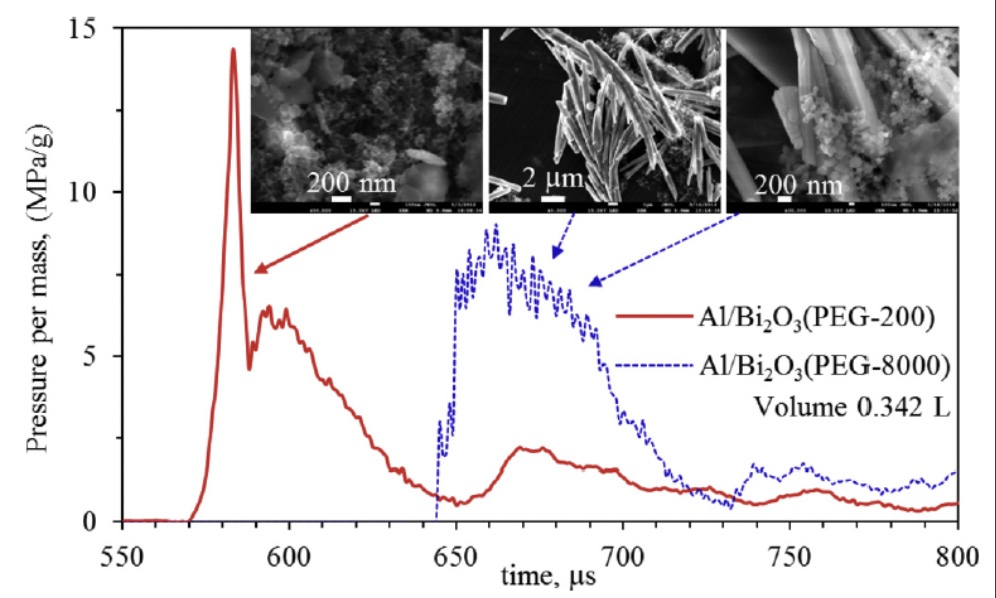

Our research group is exploring Metastable Intermolecular Composites (MICs), also known as nanoenergetic materials, which have attracted significant attention for their potential to realize the long-standing goals of high energy density storage, rapid energy release, and nanoscale integration in energetic and propulsion technologies. They are likely to become the next-generation explosives, propellants and primes as they enable flexibility in energy density and power release through control of particle size, tunable stoichiometry and choice of fuel and oxidizer. Despite intense examination by scientists and engineers worldwide the temperature progress and velocity of the thermal front propagation on the nanostructured formulations, however, gas pressure evolution and rate of gas release are not well investigated and understood. This issue has seriously impeded realization of various potential emerging applications envisioned in rocket solid fuels and explosives, which require a high-pressure discharge in a short period of time as well as in bio-defeat systems. This highlight describes principles and development of Nanoenergetic Gas-Generators (NGG) systems comprising high PV (pressure volume) values and energy densities (up to 25.7 kJ/cm 3 ) that may have several potential civil and military applications. Our study revealed that Al/Bi 2 O 3 and Al/I 2 O 5 Al/Bi(OH) 3 nanocomposites can generate a transient pressure pulse more than three times larger than that during the explosion of traditional thermite reactive mixtures.

Figure: Pressure-time graphs for nanoenergetic systems prepared with Al and Bi₂O₃ synthesized using PEG-200 and PEG-8000 surfactants; insets – SEM images of corresponding powder mixtures.

Machine Learning for Lithium-Ion Battery Materials

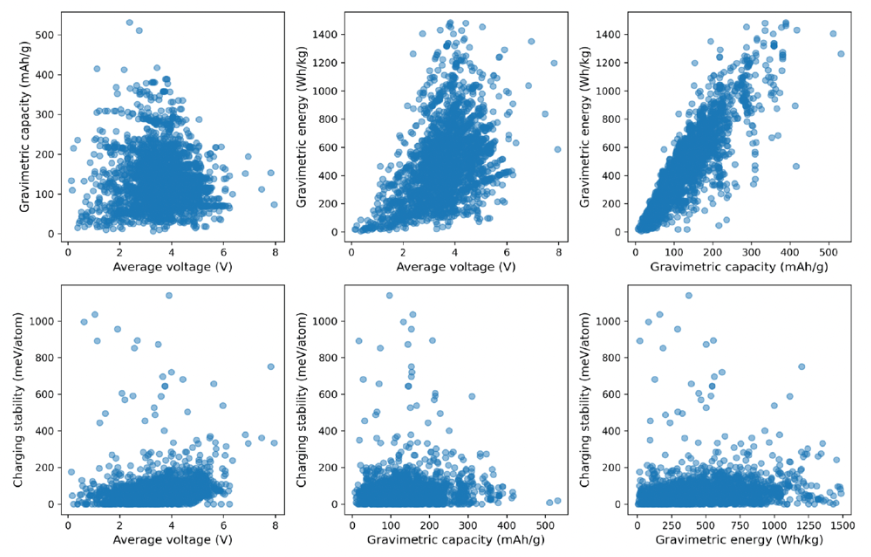

Our team is focused on development of machine learning models to predict and optimize electrochemical, structural, and stability properties of lithium-ion battery materials. By integrating computational databases, first-principles simulations, and supervised learning algorithms, the project aims to accelerate materials discovery and performance prediction for next-generation high-capacity and long-lifetime batteries. This research underscores the transformative potential of machine learning in materials science, particularly in the study of Li-ion battery electrode materials. By focusing on key features such as average operating voltage, gravimetric energy density, and charging stability, we applied the Gradient Boosting algorithm to predict gravimetric charge storage capacity, achieving an impressive R-Squared value of 0.99 and a Mean Squared Error of 20.08. These results demonstrate the efficacy of ML in accelerating materials design and optimization, fostering faster innovation, and supporting the development of sustainable energy solutions.

Figure: Scatter plot showing relationships between independent features and the target feature, highlighting a notable correlation between gravimetric energy density and charge storage capacity.

Research Faculty