Equipment and Resources

Infrared Camera (Telops) M2K

The Telops M2k is a scientific infrared camera that can capture high-speed thermal images. The Telops is used for railway inspection, tensil testing, ballisitics, and more.

Keyence VHX - 700

The VHX - 700 is the 4K Ultra-High accuracy microscope used for research that involves detailed analysis of materials.

Tescan SEM with Brucker EDS & EBSD

The Tescan is a scanning electron microscope (SEM) that can perform elemental analysis and crystallographic orientation analysis. The Tescan is really beneficial for quality control testing, failure analysis, and R&D in materials.

Induction Heating with 32 KW UltraFlex

The UltraFlex is excellent in electromagnetic induction to precisely heat conductive materials like metals, primarily used for applications like brazing, annealing, soldering, hardening, shrink-fitting, pre-heating, and post-heating in various manufacturing settings.

ABB 6-Axis Large Industrial Robot

The ABB robot is utilized in various projects at IAM, particularly in the manufacturing industry. Staying up to date with industry advancements is essential for maximizing its effectiveness.

Cold Metal Transfer WAAM (Fronius)

The Fronius is a wire arc additive manufacturing (WAAM) process that is known for its low heat input, precise control, and minimal spatter, making it ideal for building complex 3D structures layer by layer with minimal distortion and high-quality results.

EOS M290 Metal Additive Machine

With melt pool monitoring and Industrial 4.0 packages, acquired with UTRGV internal fund. Key components and specifications for the machine are as follows: Laser: 400 W Ytterbium Fiber Laser, Melt pool monitoring package, EOS Connect Industry 4.0 package. Multiple material types can be processed with high accuracy and surface finish: Ti64, MS1, CMSS, AlF357, AlSi10Mg, 20MnCrZr, MP1, CuCrZr, CuCP, IN718, IN612, 316L, and other metals as requested by industry.

Nano Dimension DragonFly for 3D

The DragonFly specializes in creating electronic circuits and devices. It uses conductive and dielectric inks to print in multiple layers and materials. The DragonFly can print antennas, arrays, and other non-planar electronics. Multiple material types can be processed with high accuracy and surface finish: Ti64, MS1, CMSS, AlF357, AlSi10Mg, 20MnCrZr, MP1, CuCrZr, CuCP, IN718, IN612, 316L, and other metals as requested by industry.

DMG Mori, CMX 50 U

The DMG Mori is a high-precision, 5-axis CNC milling machine designed for versatile machining of complex parts across a variety of materials, featuring a swivel rotary table for optimal accessibility and complete machining capabilities on complex geometries.

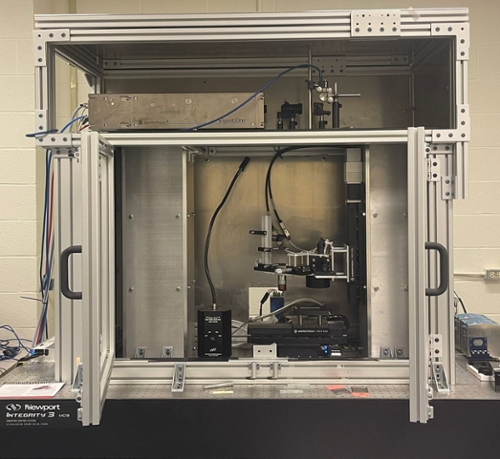

Custom Made Femtosecond Pulsed Laser

This system provides capabilities for: Bioprinting, Micromachining, Surface polishing/grinding, and hybrid manufacturing. It is composed of the following parts: Spectra Physics Femtosecond Laser with Max pulse energy: >40 µJ at 200kHz, Laser Galvanometer, Aerotech X-Y-Z stages with nanoscale resolution and submicron level accuracy. Beam delivery optics and calibration accessories, Controller and software which allow to create structures from CAD design.

Cold Spray System

At IAM, one of our projects consist of developing a Cold Spray System. This Cold Spray System is a technology that uses a high-pressure gas stream to accelerate metal powder particles at supersonic speeds, allowing them to deposit onto a surface and form a coating or structure without melting."Cold welding" the particles together through plastic deformation, making it a solid-state additive manufacturing technique used for repairs, coatings, and even building complex parts; the key feature is that the particles remain below their melting point throughout the process, hence the term "cold spray."

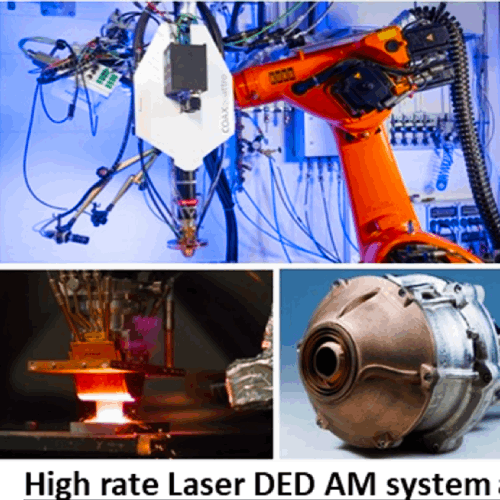

Laser DED Additive Manufacturing

IAM is developing a Laser Directed Energy Deposition that is a 3D printing process that uses a laser to build parts by melting and depositing material layer by layer.

Thermal Technology LLC DCS 10 Spark Plasma Sintering (SPS)

Acquired by NSF MRI grant. The system is based around the combination of high pressure and rapid heating due to direct current resistance heating of a conductive mold. The DCS 10 system is based around a compact and powerful high current DC power supply designed to provide smooth continuous and pulsed DC power. The other primary component of the DCS process is force supplied by the hydraulic load train. During processing of materials, by either diffusion bonding or sintering when accurate control over both high and low load situations is required, the DCS maintains precise control across the entire spectrum of force. To complement the advanced hydraulics, the DCS features a 4-column load frame design to ensure minimal deflection during pressing thereby providing precise and accurate alignment.