Energy & Semiconductor Manufacturing

The division of Energy and Semiconductor Manufacturing performs research at materials level and processes level to develop innovative functional materials, nano structures and packaging for sensing, AI, and energy storage.

2D materials for energy storage and semiconductor applications

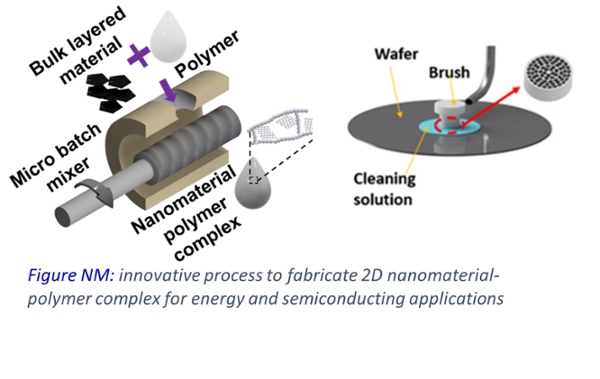

Nanomaterials such as graphene can improve the performance of energy storge and energy harvesting devices. The research group is exploring an innovative process to create nanomaterial polymer complex to obtain material solutions for energy applications (Figure NM-A).

A similar platform will also be utilized for semiconductor equipment consumables (brushes and pads) (Figure NM-B).

Ultrafast Laser-based Nano-particle synthesis and 2D/3D printing

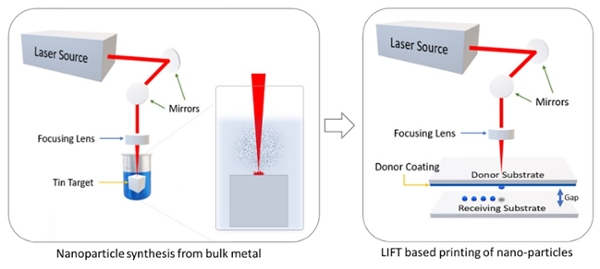

The need for smaller and more efficient printed electronics is on the rise, and while nanoparticles are the clear next step in realizing this goal due to their unique properties that cannot be detected in their bulk form, research on how to use them effectively is still in its early stages. Through a manufacturing convergence approach, researchers at CAMICS have been developing a system that can process raw materials all the way through to the final application.

Figure 2: Convergent process for nanoparticles synthesis and printing for printed electronics

For instance, at CAMICS, graduate researchers are looking into how the laser process parameters and process environment impact the morphologies of nanoparticles during ultrafast laser synthesis. Study also includes modification of the setup design of an ultrafast pulsed laser system to demonstrate both the synthesis of nanoparticles from bulk metal through Pulse Laser Ablation-in Liquid (PLA-L) and the printing of said nanoparticles utilizing the Laser Induced Forward Transfer (LIFT) method. This implementation allows for a single system to have complete control from the raw material processing stage to the final application. The benefits of having a hybrid LIFT and PLA system, including reducing costs and lead times, producing smaller and more complex printed applications, and contributing to the green manufacturing movement.

Energy Harvesting from Infrastructure

Transportation system is one of the largest and most important infrastructures in modern society. According to Federal Highway Administration (FHWA, 2012), a total lane mile of the public roads in the US is 8.6 million miles. In the US, 28% of total produced energy was consumed by transportation sector. While the moving of vehicle is the major energy consumption of the transportation sector, the transportation facilities use 25×1012 BTU of electrical energy for the roadway lighting, signal, and various sensing and monitoring systems. Additionally, about 51×1012 BTU, which is about twice that actually consumed, is lost from transmission during power delivery. This is caused by the widespread nature of roads.

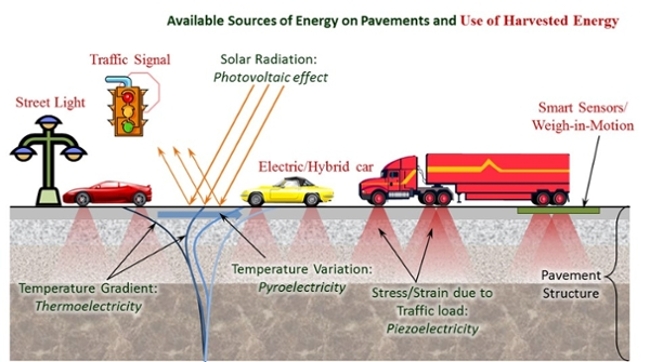

Energy harvesting reclaims otherwise dissipated or wasted energy and is highly sustainable power generation approach. While energy harvesting technology has successfully been explored in numerous electronics and mechanical systems applications, its application to roadway pavements is currently at its infancy. Since asphalt pavement is a huge storage of solar energy, the pavement energy harvesting technology promises a significant breakthrough in attaining renewable energy at a massive scale. The specific attributes of harnessing energy from pavements are: 1) the size of roadways is massive, and hence, relatively large amount of energy can be collected, 2) there exist various types of available energy sources, e.g., geothermal, solar, mechanical, etc., and 3) a long-distance power transmission is not necessary because the collected electrical energy can be consumed in place by traffic facilities. In situ generation of electrical power can decidedly offset the aforementioned transmission loss of electrical energy. In addition, it can eliminate the installation and maintenance cost of power delivery infrastructures.

Available energy sources for energy harvesting from roadway pavements and the possible use of harvested energy.

Major research topics include:

- Multifunctional paving materials for self-sensing, self-healing, thermal regulation (mitigating heat-island effect), and heated pavement for road deicing.

- Electric vehicle charging with harvested energy while driving

- Thermoelectric/piezoelectric energy harvesting

Multifunctional Paving Materials

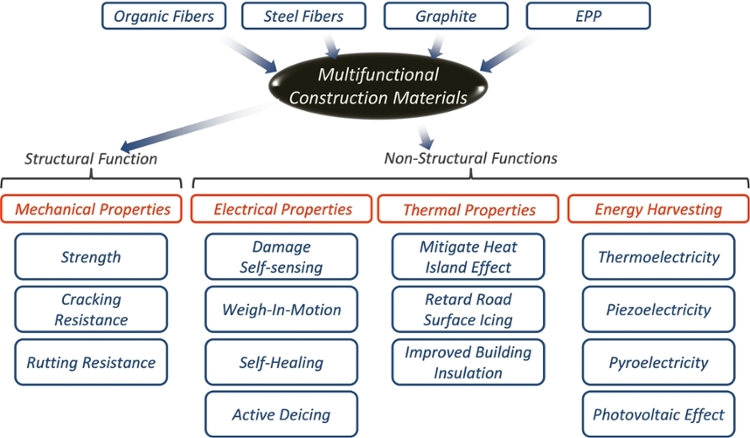

Multifunctional materials are structural materials possessing non-structural attributes beyond their basic mechanical functions. Imparting and controlling electrical/thermal conductivity enable construction materials to have novel smart functions such as piezo-electricity, piezo-resistivity, and electrical heating. Available applications of the smart functions to construction materials may include self-sensing, self-healing, temperature regulation, electromagnetic shielding, and energy harvesting. A method of controlling electrical and thermal conductivity of asphalt/concrete has been conducted, and their applications for self-sensing and heated pavement are under investigation.

Multifunctional Construction Materials and Their Possible Applications

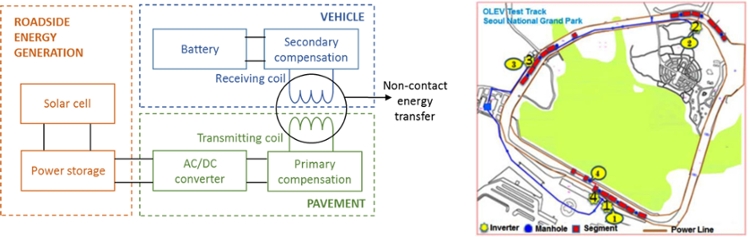

Electric Vehicle Charging While Driving

While the electric vehicle technology has higher energy efficiency and reduced pollution than fossil fuel vehicles, there are some barriers such as long charging time at power station and limited travel time. The dynamic (charging while driving) inductive charging system can be a solution to resolve these issues. In addition, energy harvesting is highly sustainable method of power generation, and can be cost effective at interstate highways away from the existing power grid. The combination of the highly sustainable power generation and inductive charging technologies will lead a breakthrough for sustainable transportation system.

Schematics of Non-Contact Vehicle Charging System

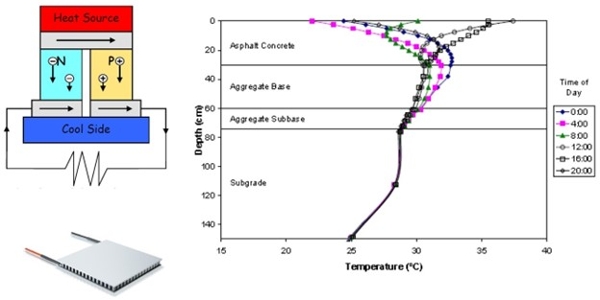

Thermoelectric/piezoelectric energy harvesting

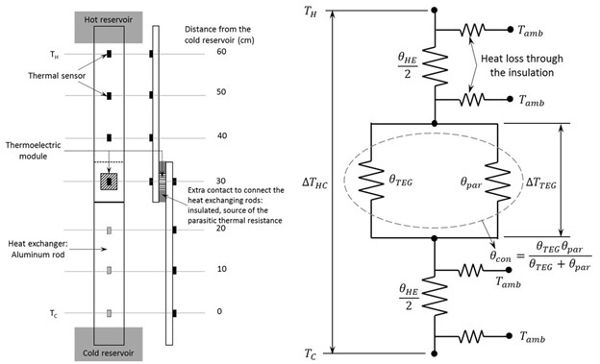

The pavement temperature distribution along the depth widely varies during a day. The temperature differences between subgrade and surface of pavements are more than 15 °C. Thermoelectric generator (TEG) converts this temperature difference into electric power. Various factors affecting the efficiency were investigated to optimize thermoelectric energy harvesting from pavements. The results obtained from the theoretical and experimental investigations indicate that the controlling of the heat flow within the system has significant effect on the useful power output. The effects of the thermal impedance and insulation of the heat exchanger are also evaluated. Among the various combinations of the TEGs and the heat exchanger geometries, the best combination of the device configuration and setup yielded over 40 mW at the road. Given the stated temperature differential, and the device capacities, the power results obtained is about 800 times higher than the power output of the one of the most recently reported study on the pavement energy harvesting using TEG.

Thermoelectric Generator and Thermal Gradient on a Pavement

Thermoelectric Generator System Optimization

Electronic packaging

Ultrasonic wire bonding is a widely applied interconnection technique in electronic packaging industry. Every second, more than 1 million interconnections are created by this technique. There are two main approaches: ball-wedge bonding and wedge-wedge bonding. Ball-wedge bonding is typically used in chips, like the chips in your computer or your cell phone. Wedge-wedge bonding is mainly used in power modules, like IGBT. Recent years, along with the development of e-mobilities, the requirement on batteries has been dramatically increasing. These batteries are composed of many cells which are then connected by wedge-wedge bonding. Wire bonding is a very fast process. For Au or Al wires, a bond is usually finished in tens of millisecond; while for Cu wires, a bond demands a longer time, up to 300 ms. In such a short period, many interesting phenomena occur, including friction, self-cleaning, ultrasonic softening, microweld formation and breakage, interdiffusion, and recrystallization.

Ultrasound is a clean energy source, which can be used for cleaning, fat reduction, etc. When ultrasound is activated in a liquid, cavitation bubbles will be generated. These bubbles first collapse and then explode. This leads to a high pressure and high temperature in the bubble center. As the bubbles get close to the object surfact to be cleaned, microjets will be produced towards the surface. These microjects create high normal and shear stresses, which can be used for cleaning. In industry, people are still using strong acids to remove contaminations like oxides. With ultrasound, the usage of acids can be greatly reduced or even avoided. Thus, our enviornment can be saved